Have your spreader tested once every three years

If the fertiliser spreader is precisely adjusted according to the correct spreading chart, it should theoretically give a correct spreading pattern. Practice, however, sometimes shows otherwise. What are the most common reasons for this and what can be done about them?

The most common reasons can be traced to:

- The fertiliser used: the physical properties of a batch of mineral fertilisers may differ from those on which the spreader manufacturer has carried out tests. As a result, you will have to use a different spreading chart if the quality is different. If this is not done, the fertiliser granules will follow a different path in practice, resulting in an anomalous spreading pattern. If the fertiliser is of insufficient quality, it is always advisable to carry out a spreader test.

- The fertiliser spreader: incorrect adjustment or wear on certain parts of the spreader lead to deviations in the spreading pattern in the form of spreading paths, which are visible only when there is a large deviation in the spreading pattern. When no spreading paths are visible, it does not always mean the distribution is good. Spreading paths in cereals and grasses usually become visible only at a coefficient of variation from 25% onwards. It is important to carry out regular spreader tests precisely because of the large difference between 0 and 25%.

Measurement = knowledge

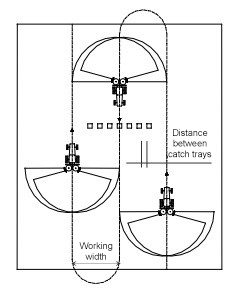

To find out whether the fertiliser spreader gives a correct spreading pattern, it is advisable to test the spreader. A spreader test is carried out by collecting the fertiliser being spread in catch trays, the contents of which are then measured. At the start of the spreader test, plastic catch trays are first deployed across the entire spreading width. When the catch trays are laid out, they should be level, in a straight line and at the same height. For optimal results, it is therefore important that the spreader test is carried out on flat ground. The distance between the catch trays will depend on the working width. The more catch trays used, the more reliable the spreader test will be.The contents of the catch trays will be processed in a calculation program. The result is displayed in a graph showing the spreading pattern, coefficient of variation and maximum deviation.

The coefficient of variation is the value for the distribution of fertiliser granules. It indicates how much the spreading pattern deviates from the theoretically ideal spreading pattern (see table). In this case, the coefficient of variation indicates the distribution accuracy of granules when mineral fertilisers are being spread. If the value deviates by more than 10%, it will affect the yield.

| Assessment of coefficient of variation | |

|---|---|

| Coefficient of variation | Assessment |

| 0-5% | Excellent |

| 5-10% | Good |

| 10-15% | Acceptable |

| >15% | Unacceptable |

If the spreading pattern is poor, readjust the fertiliser spreader’s settings. Fertiliser spreaders that have been tested by a certified company and were found to be working properly are given a seal of approval (Roelofs, 2010). The average cost of a spreader test is €200.

Points to consider when performing a spreader test

The following aspects are important when testing a spreader or having a spreader tested:

- At least once every three years, have your spreader tested by a professional spreader calibration and advisory company;

- If the test is conducted by a certified company: set clear goals beforehand, be critical and ask questions. Use the spreader test as a learning opportunity.

- Check whether the fertiliser meets the specified requirements and is of sufficient quality by measuring the fraction composition, hardness and bulk weight.

- When laying out the catch trays:

- Make sure they are in a straight line;

- Make sure they are level and horizontal on flat ground;

Incorrect placement of the catch trays greatly affects the test result. This can result in deviations of up to 15%;

- Test the spreader across the entire spreading width. Testing only one side of the spreader gives unreliable results. In theory, a spreader should have an equal spreading pattern on both sides but, in practice, there could be a deviation between the two sides. Lay out the catch trays across the entire spreading width and drive the spreader exactly in the middle of the row of catch trays. Sometimes it is not possible to place the catch trays across the entire spreading width. In this case, place the catch trays across half a spreading width and test each side of the spreader separately.

- During the spreader test, also check the boundary spreading device on the fertiliser spreader. In this case, it makes no sense to calculate the coefficient of variation, because a boundary spreading pattern does not involve an entire plot. However, it is possible to check how much fertiliser falls outside the plot and how the next pass follows on;

- To ensure the results are processed correctly, it is important that the fertiliser granules are collected in the correct manner. Avoid losing granules when emptying the catch trays and work carefully.

Also test the overlap

When performing a spreader test, it is also important to test the overlap. The illustration shown features an example of a spreader test in which this was also done.

In any spreader test, spreading should start on time and not stop too soon, so that all fertiliser can be collected. In the example shown, three paths were spread to determine the overlap. The contents of the catch trays were emptied into a measuring tube.

The spreading pattern and overlap become clear in the measuring tubes. Measuring tube ① shows an optimal overlap. There is too little overlap in scenario ② and too much overlap in scenario ③.

More information

For more information on fertiliser spreader testing, please refer to your spreader manual or contact the spreader manufacturer. The spreader manual always contains basic information on the best way to test your spreader.

Sources:

Bogballe, 2014.

Huijsmans, Toedieningsnauwkeurigheid dierlijke mest, 2011.

Huijsmans, 2011.

Persson, 2014.

PTC+, 2003

Smits, Strooien over het gewas vergt precisie, 2008